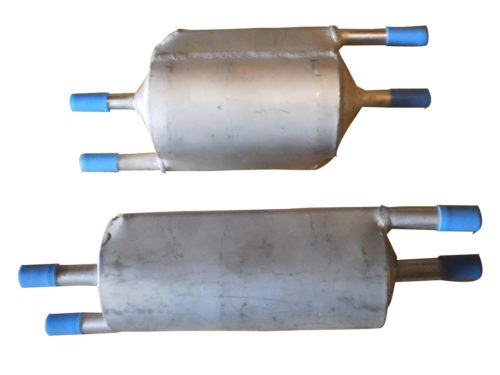

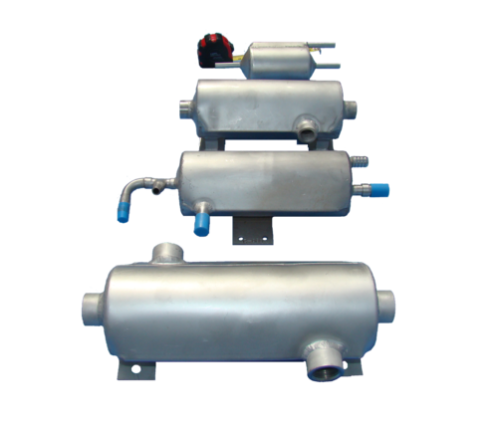

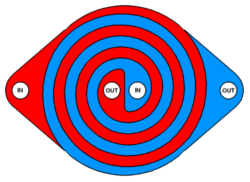

The Elanco Encoil is based off of our Type C Spiral Heat Exchanger. The Encoil has several advantages over the shell & tube and plate heat exchangers. The curved path of the spiral gives better heat transfer coefficients at lower pressure drops and the constant scrubbing action keeps the surface clean. This means the spiral will give longer service without the cleaning maintenance that accompanies other types of heat exchangers. The standard Encoil is fabricated from stainless steel, which will not corrode in most processes and it is completely welded, which eliminates the problems of rolled or brazed joints. Also, Encoils are very compact, often giving the same heat transfer area in 1/2 the space required of a shell & tube heat exchanger.

The Elanco Encoil is based off of our Type C Spiral Heat Exchanger. The Encoil has several advantages over the shell & tube and plate heat exchangers. The curved path of the spiral gives better heat transfer coefficients at lower pressure drops and the constant scrubbing action keeps the surface clean. This means the spiral will give longer service without the cleaning maintenance that accompanies other types of heat exchangers. The standard Encoil is fabricated from stainless steel, which will not corrode in most processes and it is completely welded, which eliminates the problems of rolled or brazed joints. Also, Encoils are very compact, often giving the same heat transfer area in 1/2 the space required of a shell & tube heat exchanger.

Applications

By a large margin, the most popular application of the Encoil is heating and cooling deionized (DI) water. This is often inside another machine such as a lasers or X-rays. DI water is most often generated with cartridge resins and circulated by a pump with low pressures of less than 75 psi; therefore, DI water is very corrosive and requires vessels made from stainless material.

Examples of Applications

High Powered Electronics:

- Lasers

- Radars

- Microwaves

- Large Capacitors

- Large Transformers

- Rectifiers

Test Equipment & Instruments

Sample Coolers

Swimming Pools & Spas

Steam Boiler Feed Heater & Blowdown Coolers

Trim Coolers

Small Scale Distillation:

- Condensers

- Feed Heaters

- Interchangers

- Reboilers